In the automotive supply chain, a single faulty door handle or sensor can trigger a multi-million dollar recall. For Tier 1 suppliers, compliance with IATF 16949 is not just about quality management; it is about Full Lifecycle Traceability.

Modern automation is the only bridge between raw components and verifiable safety.

1. The "Digital Twin" of Every Part

Manual assembly leaves no digital footprint. In contrast, smart assembly cells function as data hubs.

Through integration with MES (Manufacturing Execution Systems), every process step is recorded:

Torque Monitoring: The exact torque value (N·m) and angle for every screw are logged.

Process Interlocking: If a step fails (e.g., insufficient grease dispensing), the system locks the pallet, preventing the defective part from moving to the next station.

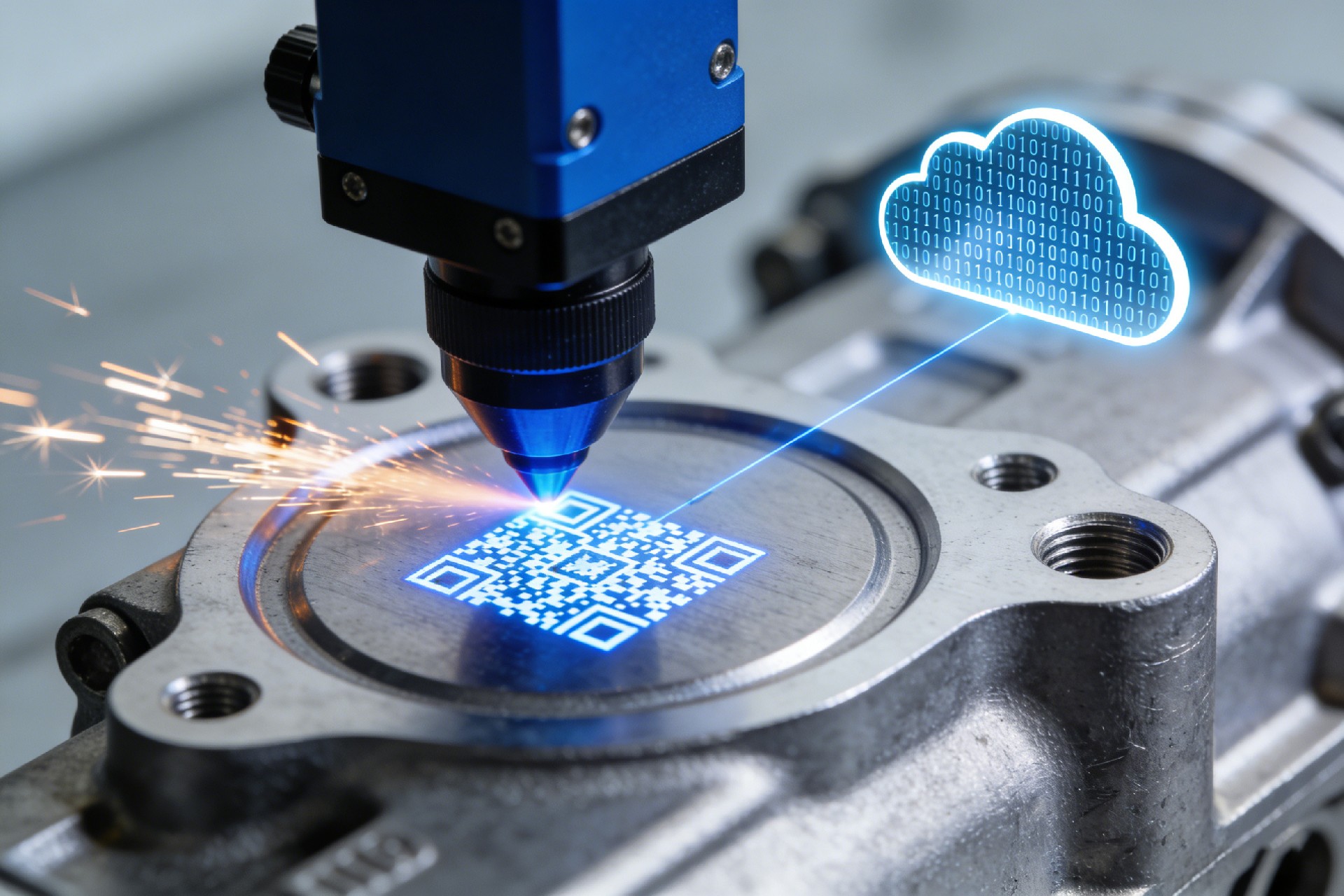

Laser Marking: A unique Data Matrix code is laser-etched onto the finished product, linking it permanently to its production data. This creates a "Digital Twin" for liability protection.

2. Protecting the "Class A" Surface

As vehicles move towards premium aesthetics (e.g., hidden door handles, PVD finishes), the cosmetic quality of parts is paramount.

Standard automation can scratch delicate surfaces. The solution lies in Non-Marking Handling Technologies.

Soft-Touch Grippers: Using materials like PEEK or vacuum suction instead of hardened steel jaws.

Segregated Stamping: Performing high-force operations (like riveting the lock chassis) in a separate module before mating with the painted handle cover. This "Force Isolation" logic ensures the aesthetic surface remains pristine.

Company Phone:0755-29429358

Domestic Business Manager:+86 18148550476(Ms.Huang)

Ms.Huang Email:sales@zeuee.com

Overseas Business Manager:+86 13923753830(Ms.Dai)

Ms.Dai's Email:trade@zeuee.com

After-sales Service:+86 13922806890(Mr.Kang)

Company Email:sales@zeuee.com

Shenzhen Zeyu Intelligent Industrial Technology Co., Ltd