Introduction: The "Hidden" Quality Crisis

In the global hardware market, many brands focus heavily on promoting raw materials—Stainless Steel 304, Zinc Alloy, or Brass. While material is the foundation, industry data reveals that over 60% of door handle failures (loosening, jamming, or internal rusting) are not due to poor materials, but imprecise assembly processes.

For top-tier hardware manufacturers in 2025, the competitive edge has shifted from "what you make it with" to "how you put it together."

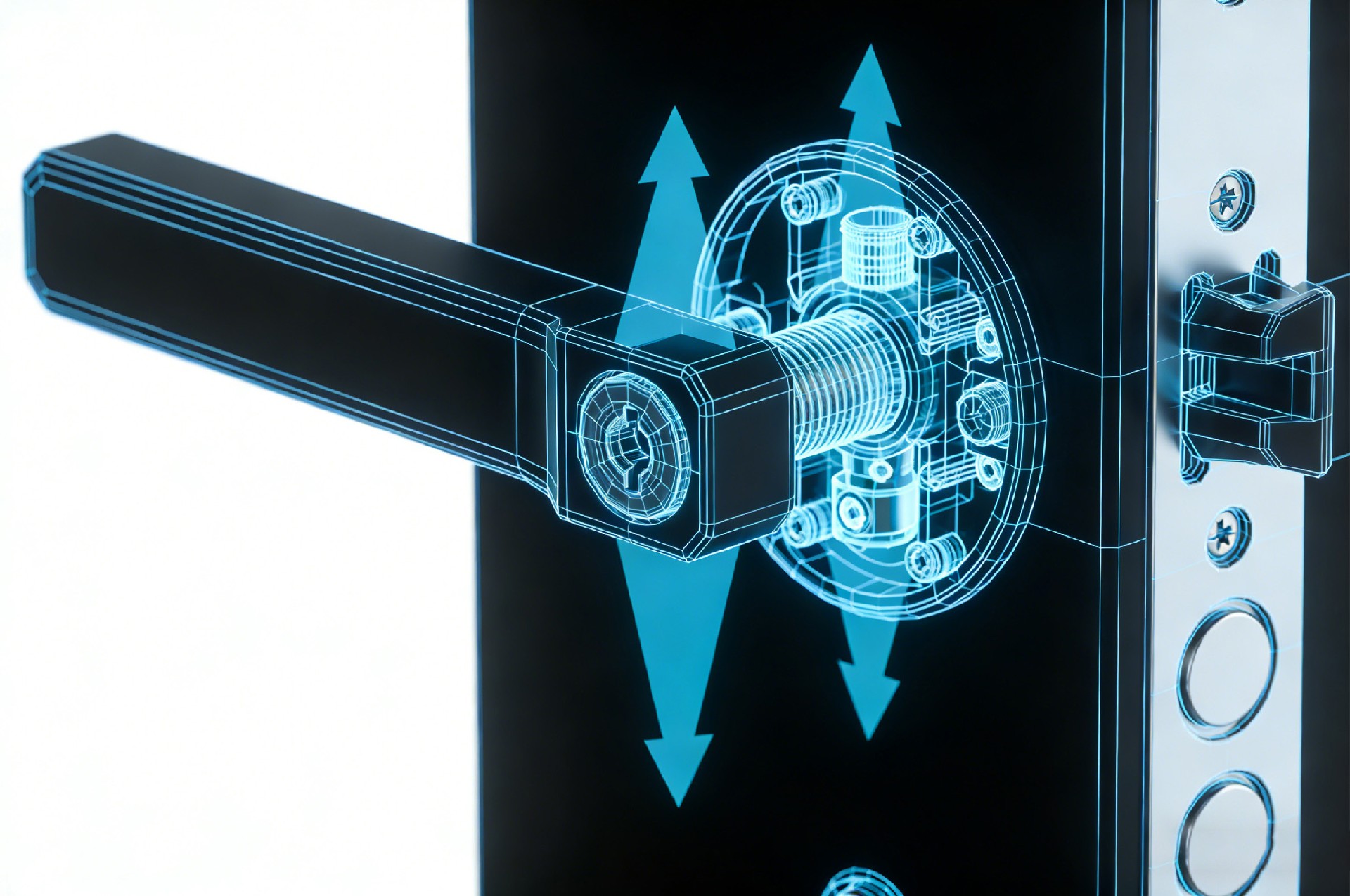

1. Solving the "Wobble": The Evolution of Stamping Technology

One of the most common complaints from end-users is the "wobbly handle"—where the handle feels loose against the spindle after a few months of use.

The Root Cause: In traditional manufacturing, the connection between the lock cylinder and the square spindle often relies on single-point impact stamping. This can lead to uneven stress distribution.

The Modern Solution: Advanced manufacturing lines have moved towards V-Groove Hydraulic Stamping. Unlike manual impact, this technology applies simultaneous, balanced pressure from multiple angles. It ensures the spindle is perfectly centered and locked with industrial-grade consistency. This method eliminates the gap tolerance that causes loosening, giving the handle a solid, premium mechanical feel that lasts for years.

2. The Invisible Shield: Lubrication as a Sealing Strategy

2. The Invisible Shield: Lubrication as a Sealing Strategy

Why do internal mechanisms rust even in "rust-proof" handles? Often, it is because moisture and dust penetrate the microscopic gaps between moving parts.

The Insight: Grease is not just for movement; it is for sealing.

The Process Upgrade: Leading manufacturers now utilize Dual-Stage Automated Injection.

Stage 1: Lubricates friction points for silence.

Stage 2: Fills the assembly gaps (between washers and guide sleeves) to create an airtight seal.

By automating this process, factories ensure every unit has the exact amount of sealant required to block environmental elements, significantly outperforming manual greasing methods.

3. Aesthetics vs. Mechanics: The Modular Assembly Logic

A paradox in hardware manufacturing is that the processes required to make a handle strong (high-pressure stamping) are often the ones that damage its surface (scratches and dents).

The Innovation: To protect the delicate surface finish of premium handles (especially PVD or matte black finishes), modern assembly lines have adopted a "Pre-Assembly" Modular Logic. High-force structural components (like the lock core and spindle) are assembled and stamped in an isolated module before being integrated with the decorative handle body. This separation of "force" and "finish" ensures zero cosmetic defects while maintaining structural integrity.

Conclusion

For B2B buyers and brand owners, sourcing high-quality door handles requires looking beyond the spec sheet. The true mark of quality lies in the invisible details: the balance of the stamping, the precision of the lubrication, and the logic of the assembly line. In the era of automation, process precision is the new premium.

Company Phone:0755-29429358

Domestic Business Manager:+86 18148550476(Ms.Huang)

Ms.Huang Email:sales@zeuee.com

Overseas Business Manager:+86 13923753830(Ms.Dai)

Ms.Dai's Email:trade@zeuee.com

After-sales Service:+86 13922806890(Mr.Kang)

Company Email:sales@zeuee.com

Shenzhen Zeyu Intelligent Industrial Technology Co., Ltd