Introduction: The End of the "Cheap Labor" Era

For decades, the global hardware industry relied on a simple equation: more orders = more workers. But in 2025, this model is breaking down. With rising labor costs across Asia and increasing demands for precision from European and American buyers, the "manual assembly" model is becoming a bottleneck.

For manufacturers of complex hardware like the 23010 handle series, the challenge is no longer just "making it fast"—it is about consistency, flexibility, and data control.

1. The "8-Part" Complexity Trap

To the consumer, a door handle is a single object. To a manufacturer, it is a complex puzzle of 8 distinct components (Handle, Guide Sleeve, Washers, Cylinder, Pins, Spindle, Covers, Screws).

The Manual Problem: Assembling 8 parts manually creates exponential room for error. A missed washer or a loose screw is human nature when fatigue sets in after 4 hours of work.·

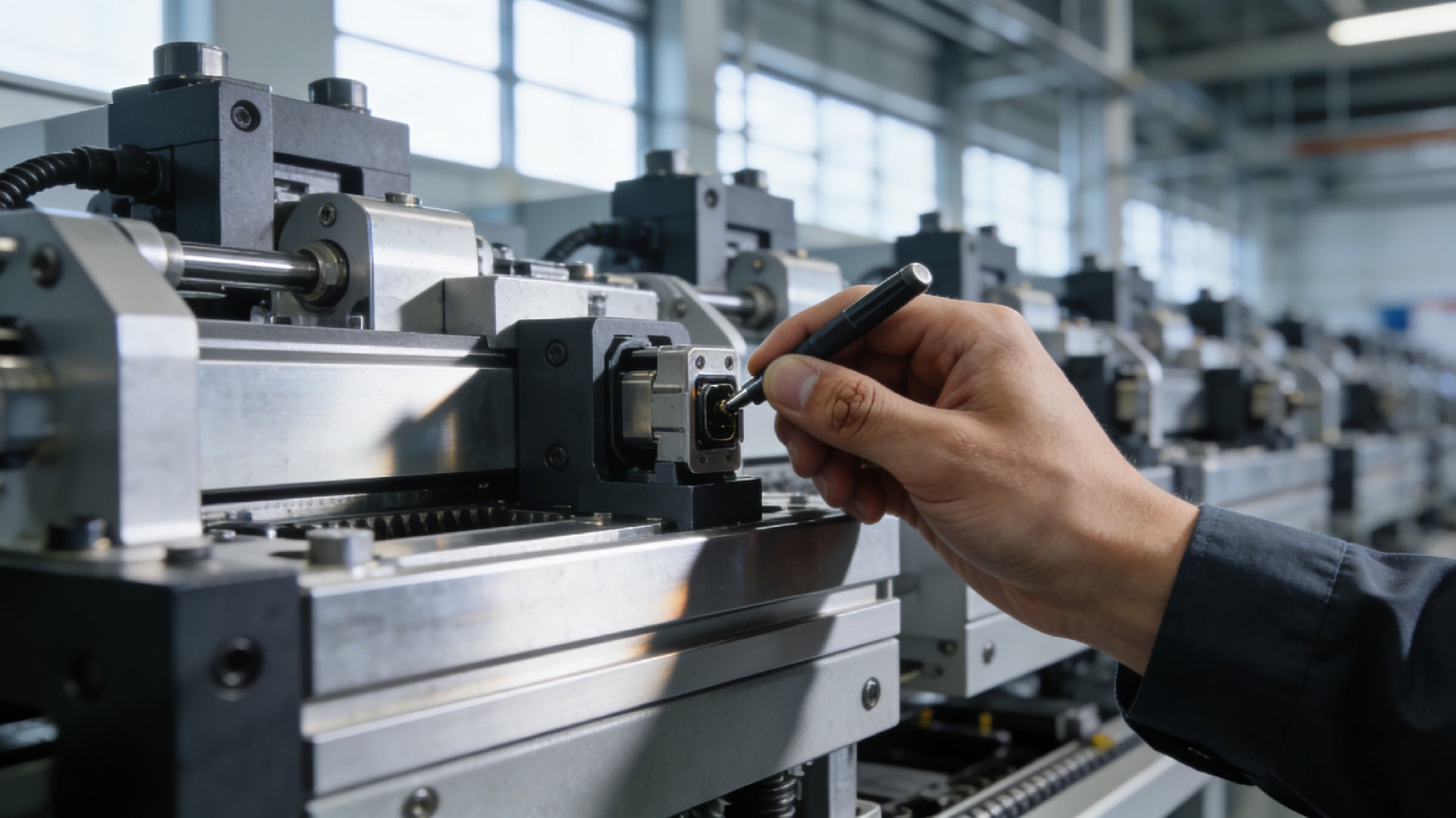

The Automated Advantage: Modern rotary assembly systems turn complexity into a standardized flow. By integrating vibratory bowl feeding for all 8 parts, automation ensures that Component A never proceeds to Component B unless it is perfectly positioned. It transforms a chaotic manual bench into a rhythmic, error-free cycle of 16-18 units per minute.

2. Myth-Busting: Automation is Not "Rigid" Anymore

A common fear among global factory owners is: "If I buy a machine, I can only make one product. What if the market changes?"

This was true ten years ago. Today, the game has changed.

The New Standard: Flexible Modular Design.

Top-tier assembly machines now feature "Quick Changeover" technologies. For a handle assembly line, switching between different handle shapes or spindle sizes can now be done in under 15 minutes.

Why it Matters: This allows manufacturers to accept smaller, diverse orders (e.g., 500 units of Model A, followed by 1000 units of Model B) without downtime, effectively competing with the agility of manual labor but with the speed of robots.

3. Data: The New Quality Assurance

In a manual line, you only know a product is defective when the customer returns it.

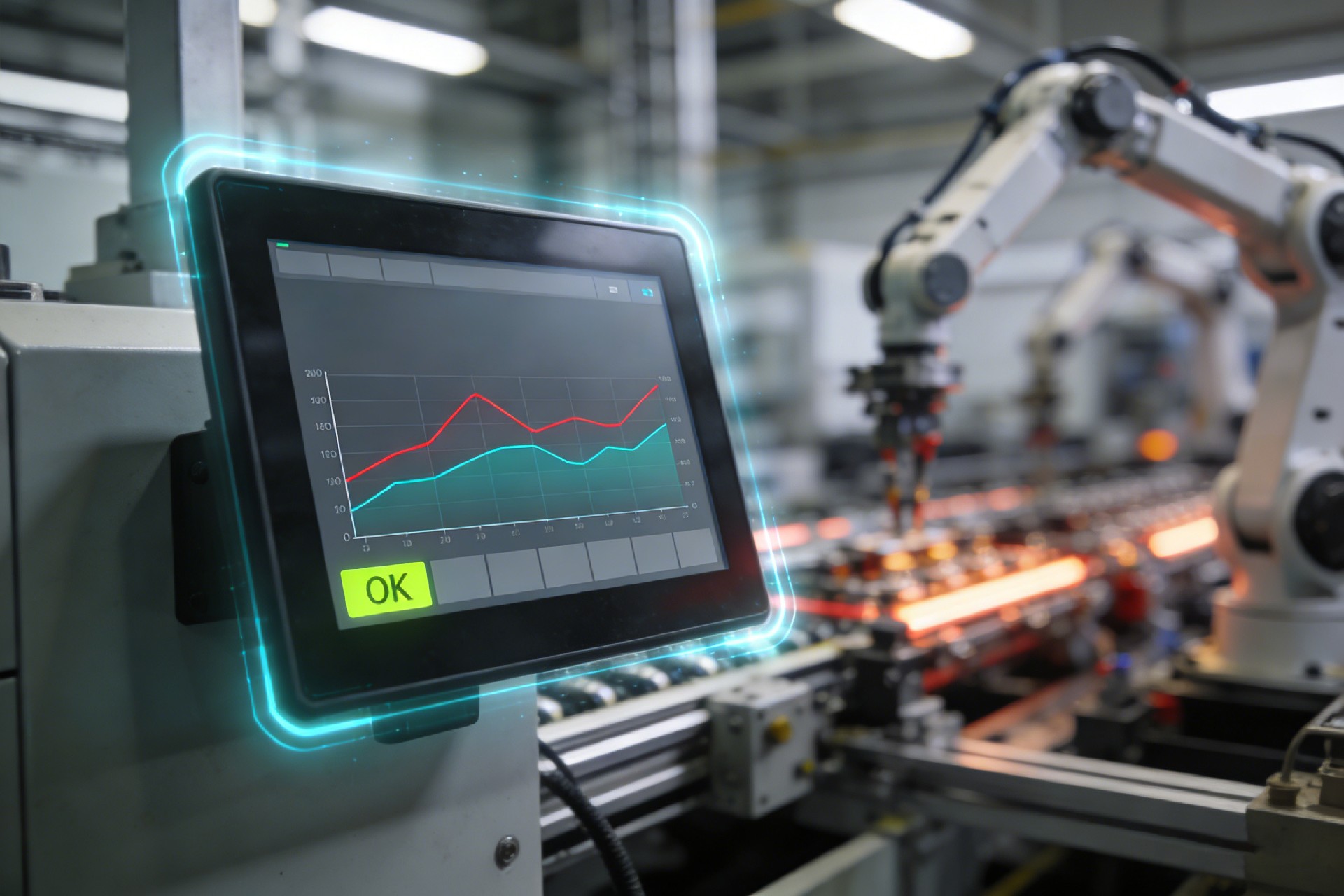

Smart assembly machines introduce Data Visualization (PLC + Touch Screen HMI) to the factory floor.

Real-time Monitoring: The machine tracks capacity, pass rates, and cycle times in real-time.

Predictive Maintenance: Instead of waiting for a breakdown, the system alerts operators when a station (e.g., the screwing module or stamping hydraulic) needs adjustment.

Transparency: For global buyers, knowing that their supplier uses a data-driven process provides immense confidence in supply chain stability.

Conclusion

Conclusion

The transition to automation is not just about replacing hands with steel; it is about replacing "uncertainty" with "predictability." For hardware manufacturers looking to scale in the global market, investing in a high-efficiency, flexible assembly system is no longer an option—it is the baseline for survival.

Company Phone:0755-29429358

Domestic Business Manager:+86 18148550476(Ms.Huang)

Ms.Huang Email:sales@zeuee.com

Overseas Business Manager:+86 13923753830(Ms.Dai)

Ms.Dai's Email:trade@zeuee.com

After-sales Service:+86 13922806890(Mr.Kang)

Company Email:sales@zeuee.com

Shenzhen Zeyu Intelligent Industrial Technology Co., Ltd