You can have the fastest robot arms and the smartest PLC, but if the feeder jams, production stops. In hardware assembly, dealing with complex geometries—like irregular door handles, springs, or interlocking clips—is the biggest technical bottleneck.

Reliable feeding is not just about vibration; it's about physics and geometry.

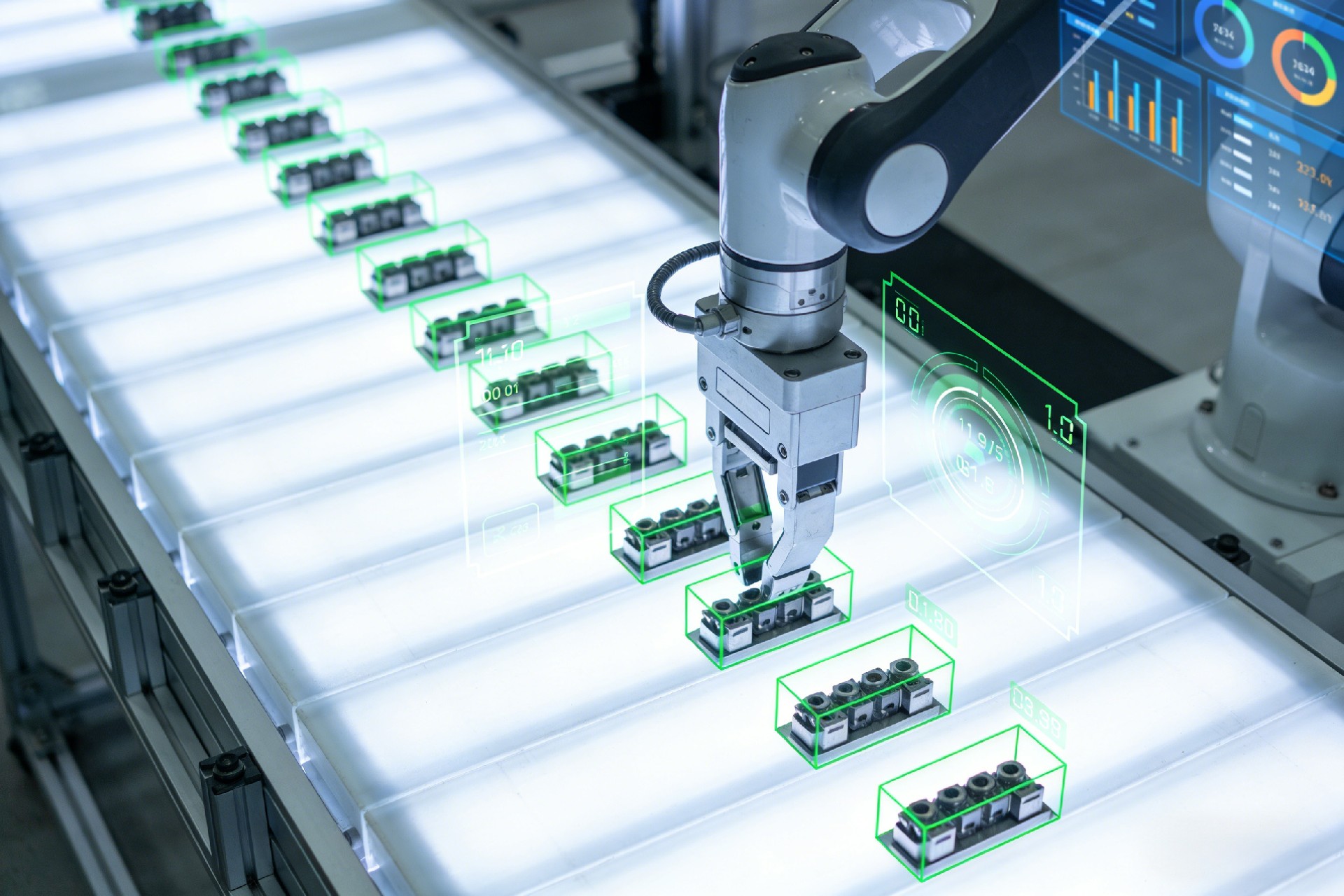

Visual Concept: A close-up, high-speed photography shot of metal parts flowing smoothly in a spiral vibratory bowl feeder. The metal parts are blurred slightly to show motion.

1. Taming the "Irregular" Parts

Standard vibratory bowls struggle with parts that tangle (like springs) or parts with subtle asymmetry.

Advanced automation providers utilize Multi-Stage Screening Mechanisms. Before a part reaches the robotic pick point, it passes through customized mechanical traps that reject incorrectly oriented parts back into the bowl.

For delicate surfaces (like PVD-coated handles), Flexible Feeding Systems (using voice coil actuators and vision cameras) are used to gently flip parts without the abrasive friction of traditional bowls.

2. Vision-Guided Orientation

How do you feed a part that looks almost identical on both sides?

The answer is Vision Integration. By placing a high-speed camera above the feeder track, the system identifies the part's rotation (0° vs 180°) in milliseconds. Instead of jamming, the system signals a rotary actuator to correct the part's orientation on the fly.

3. Noise and Stability

A jammed feeder creates downtime; a noisy feeder creates a hazardous workplace.

High-quality feeding systems incorporate Sound-Proof Enclosures and frequency-tuning controllers to maintain a stable flow rate regardless of the material load, ensuring the assembly line maintains its 18 pcs/min rhythm without interruption.

Company Phone:0755-29429358

Domestic Business Manager:+86 18148550476(Ms.Huang)

Ms.Huang Email:sales@zeuee.com

Overseas Business Manager:+86 13923753830(Ms.Dai)

Ms.Dai's Email:trade@zeuee.com

After-sales Service:+86 13922806890(Mr.Kang)

Company Email:sales@zeuee.com

Shenzhen Zeyu Intelligent Industrial Technology Co., Ltd