When upgrading a factory, the first dilemma a CEO faces is: "Should we buy a cheaper standard machine, or invest in a custom solution?"

While standard equipment offers a lower upfront cost, data from the manufacturing sector reveals a different story. In complex assembly scenarios—such as automotive locks or precision connectors—standard machines often lead to higher "hidden costs" in the form of retrofitting, lower yield rates, and limited flexibility.

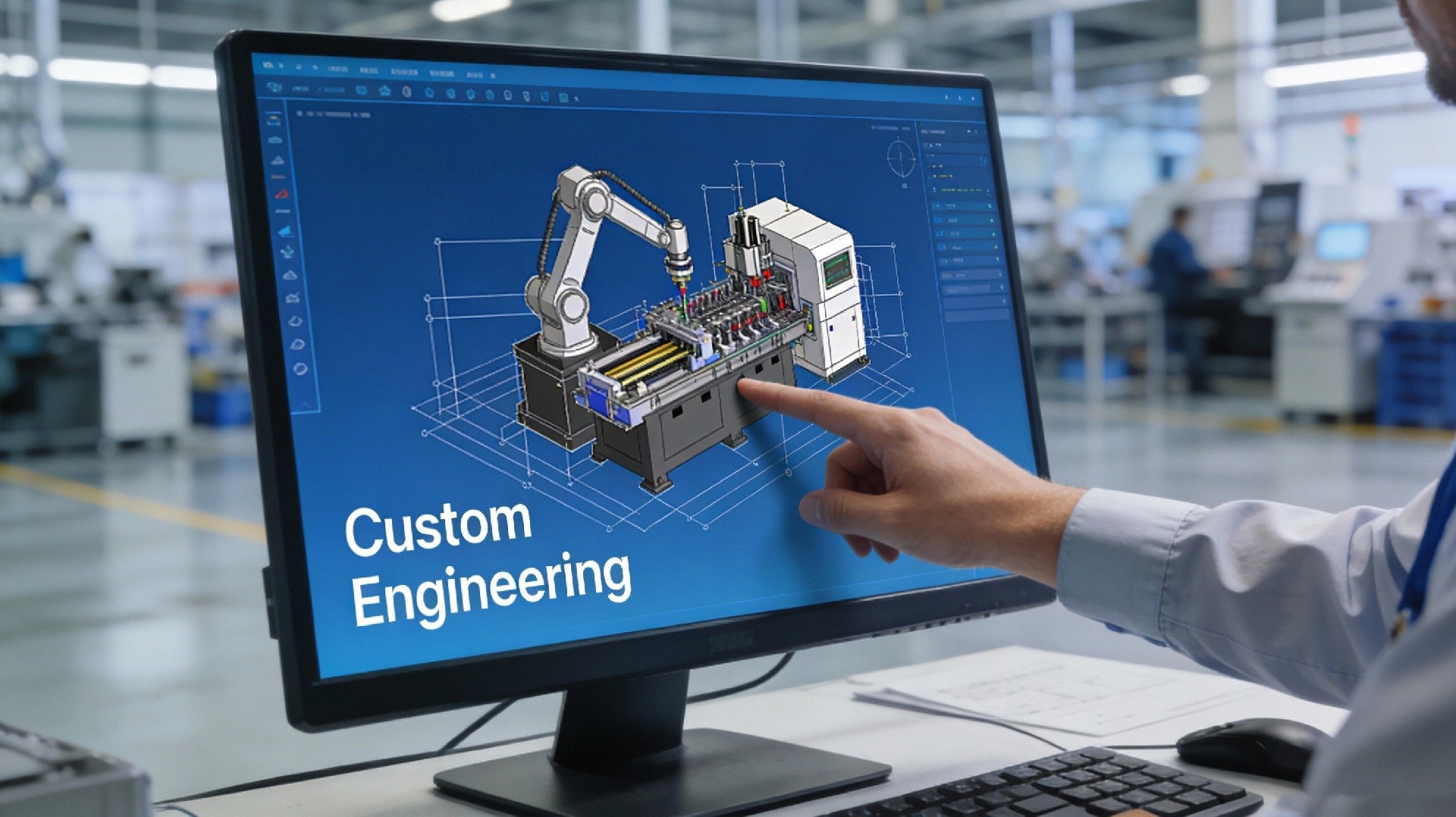

1. Adaptability to Process, Not Vice Versa

Standard machines require you to change your product design to fit the machine. Custom Automation (like the solutions provided by R&D-focused firms) designs the machine to fit your product.

For example, in assembling the 23010 handle series, the integration of 8 different components requires a unique layout that no catalog machine can offer. A bespoke design ensures that every hydraulic stamp and lubrication point is placed exactly where the process demands, optimizing OEE (Overall Equipment Effectiveness).

2. The "Future-Proofing" Factor

Markets change. A standard machine is rigid.

High-end custom solutions are built with Modularity in mind. When your product dimensions change next year, a custom-built system with quick-change tooling allows you to adapt in minutes, rather than scrapping the entire machine. This extends the equipment's lifecycle from 3 years to 10+ years.

3. The ROI Verdict

Although custom automation may require 30% more initial capital, the reduction in labor (replacing 5-10 workers) and the increase in quality (99.9% yield) typically deliver a Return on Investment (ROI) in under 14 months.

Company Phone:0755-29429358

Domestic Business Manager:+86 18148550476(Ms.Huang)

Ms.Huang Email:sales@zeuee.com

Overseas Business Manager:+86 13923753830(Ms.Dai)

Ms.Dai's Email:trade@zeuee.com

After-sales Service:+86 13922806890(Mr.Kang)

Company Email:sales@zeuee.com

Shenzhen Zeyu Intelligent Industrial Technology Co., Ltd